THE CASCADE APPROACH: SEGREGATION BY AIRFLOW DESIGN N STEAD OF BY ROOM PRESSURE

Authors:

Ir. Frans W. SaurwaltKeywords:

Segregation, Room pressure, Airflow/Pressure Cascade, Stability, Wind attack, Reduced Energy Consumption, reduced costs of installationAbstract:

Governmental inspection bodies as well as internal quality departments have enforced adherence to monitoring of room pressure as a critical aspect. And because of that, the pharmaceutical and medicaldevices and healthcare industry puts a strong emphasis on controlling room pressure itself. As clean room construction becomes better and better, resulting in very limited leakage, active room pressure control

becomes more and more complex. With a narrow focus on room pressure control and monitoring, the broader contamination control perspective and a useful different approach is overlooked. Room pressure

control is only one aspect of the concept of segregation of zones of different classes. The broader view has many benefits. This approach is based on designing on airflow in stead of mere room pressure.

While citing ISO 14644-3, and -4 as well as the EU-GMP-vol 4 Annex 1 it can be demonstrated that there is a basis for designing an overflow / pressure cascade. This cascade approach when compared to various other

systems shows to have many benefits; increased protection of the controlled environment, less complexity, better stability, reduced energy-consumption and reduced costs.

Article:

Introduction

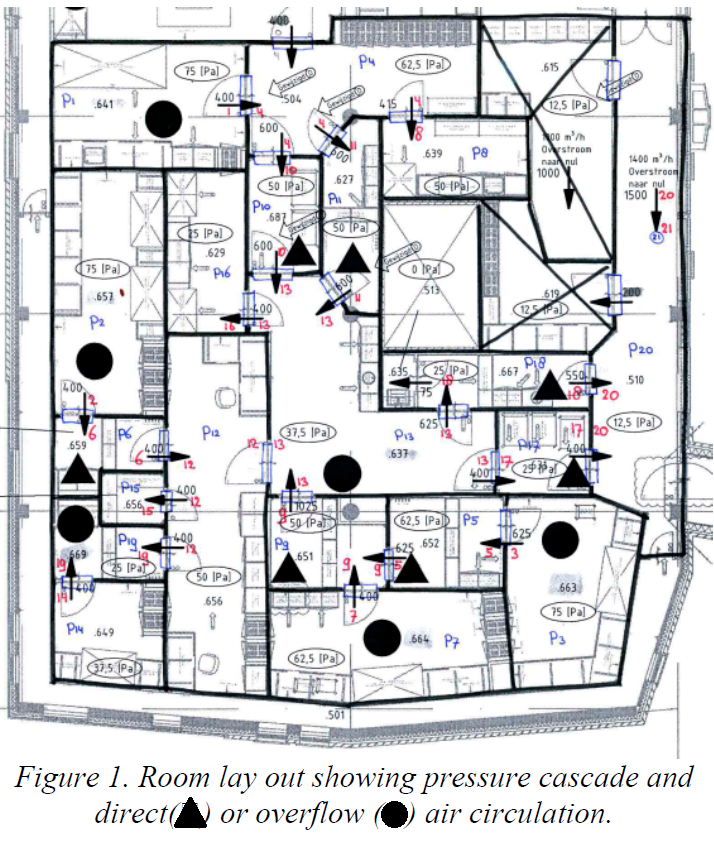

Specifying an overpressure in clean room design is a common contamination control concept. Normally a standard pressure interval (commonly 10 – 15 Pa) per step is added upwards along with the increase in

classification. Depending on the number of steps the “nominal” pressure of the various rooms can ad up to about 75 Pa. Such a design could be illustrated as shown in figure 1.

In order to achieve this the HVAC needs to be designed to control the room pressure by some means. Most commonly this is done by utilizing pressure controlled actuated dampers in the return

ducting. These dampers have to be designed to modulate in a certain airflow range and with a specific accuracy and speed of reaction. As this requires adequate understanding and designing

specific to the situation, in many cases this is not fully successful. Understanding the mechanism that will create a room pressure is essential as well as those that influence it.

Click to Download PDF

Click to Download PDF